Stainless Steel Polishing is a key surface treatment process aimed at enhancing the smoothness and appearance of stainless steel surfaces. This process is crucial for improving the aesthetic quality and performance of stainless steel products. During the polishing process, scratches, unevenness, and other defects on the surface of the stainless steel are typically removed to achieve a certain level of smoothness and shine. Through this treatment, not only can the appearance of stainless steel be improved, but its corrosion resistance and resistance to contamination can also be enhanced, which is significant for extending the service life of stainless steel products.

Stainless steel polishing can be achieved through various methods, including mechanical polishing, chemical polishing, and electrolytic polishing. Mechanical polishing is a traditional method that uses abrasive materials (such as sandpaper or polishing wheels) to physically grind away the rough surface layers. This method is simple and straightforward but may not achieve ideal results in some complex or fine applications. Chemical polishing involves using chemical agents to dissolve small protrusions on the metal surface to achieve a smooth effect, which is more effective for handling irregular surfaces or areas that are difficult to machine. Electrolytic polishing smooths the surface through electrochemical reactions in a specific electrolyte solution, offering high-quality surface treatment while maintaining the material's intrinsic properties.

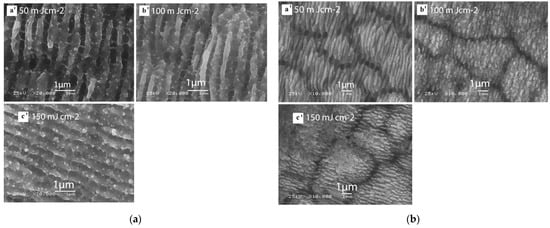

AISI 304 stainless steel corrugation processing in an air environment. (a) Central areas of the ablation region for different fluxes, (a') 50 mJ cm−2; (b') 100 mJ cm−2; (c') 150 mJ cm−2; (b) Peripheral areas of the ablation region for different fluxes, (a') 50 mJ cm−2; (b') 100 mJ cm−2; (c') 150 mJ cm−2. "Reprinted with permission from reference [38], © Springer Nature 2013."

In practical applications, stainless steel polishing plays an important role in many industries. For example, in the construction industry, polished stainless steel is widely used for decorating and protecting architectural elements such as handrails, door handles, and exterior cladding. These applications not only require stainless steel to have a good appearance but also to have sufficient weather resistance and corrosion resistance. In the automotive industry, polished stainless steel is used to enhance the aesthetic appeal and corrosion resistance of vehicles, especially in decorative parts and exhaust systems. In the food processing and medical device fields, polishing not only improves the aesthetic quality of the stainless steel surface but also helps improve its cleanliness and antibacterial properties, which are essential for maintaining hygiene and preventing contamination.

In recent years, with technological advancements, femtosecond laser polishing technology has shown unique advantages in certain specific applications. Femtosecond laser polishing can be carried out without contacting the material, precisely removing small portions of surface material with the high energy of the laser beam, achieving high precision and high-quality surface treatment. This technology is particularly suitable for stainless steel parts that require high precision and complex shapes, such as precision mechanical components and complex medical devices. Due to the unique properties of femtosecond lasers, it can perform precise material removal without creating a heat-affected zone, which is crucial for preserving the original properties and structural integrity of the material. Additionally, femtosecond laser polishing reduces the particulate contamination that may arise in traditional mechanical polishing, providing a cleaner and safer working environment.

In summary, stainless steel polishing technology is an essential process widely used in many industries. With the development of femtosecond laser technology, new possibilities have emerged for this field, improving polishing efficiency and quality while providing new solutions for complex and high-precision stainless steel processing.

References:

(1)Xiaofeng Xu et al. "Micro/Nano Periodic Surface Structures and Performance of Stainless Steel Machined Using Femtosecond Lasers." Micromachines, 13 (2022). https://doi.org/10.3390/mi13060976.

(2)Matina Vlahou et al. "Fabrication of Biomimetic 2D Nanostructures through Irradiation of Stainless Steel Surfaces with Double Femtosecond Pulses." Nanomaterials, 12 (2022). https://doi.org/10.3390/nano12040623.

(3)Liguang Yang et al. "Effect of EDM and Femtosecond-Laser Groove-Texture Collision Frequency on Tribological Properties of 0Cr17Ni7Al Stainless Steel." Coatings (2022). https://doi.org/10.3390/coatings12050611.

(4)Lingjian Meng et al. "Femtosecond Laser Treatment for Improving the Corrosion Resistance of Selective Laser Melted 17-4PH Stainless Steel." Micromachines, 13 (2022). https://doi.org/10.3390/mi13071089.

AI Assistant

AI Assistant