Periodic Surface Structures (PSS) are a phenomenon where regular microscopic or nanoscopic structures are formed on the surface of materials. These structures are typically generated by laser irradiation on solid surfaces, especially when using short-pulse lasers such as femtosecond lasers.

The formation of periodic surface structures is based on the complex physical processes involved in the interaction between the laser and the material, including optical interference, local field enhancement, thermal effects, and nonlinear optical effects. The high-intensity light field generated by femtosecond lasers on the material surface interacts with the surface, creating an optical interference pattern. This interference pattern induces local rearrangement of the material's structure under the influence of the light field, leading to the formation of periodic surface structures. The ultrashort pulses and high peak power of femtosecond lasers create strong nonlinear optical effects on the material surface, such as multiphoton absorption and plasma generation, which help precisely modify the surface structure of the material.

The processing process begins with selecting an appropriate material, such as metals, semiconductors, or polymers. The surface of these materials must be cleaned to ensure the precision of laser processing. The periodicity of these structures is typically related to the wavelength of the incident laser but can also be adjusted by varying femtosecond laser parameters such as pulse duration, energy density, repetition rate, and scanning speed. These parameters influence the precision of the processing and the characteristics of the periodic structures. The femtosecond laser scans the material surface, and the interaction between the laser and the material induces small structural changes on the surface, forming a periodic pattern. After processing, microscopes or other imaging techniques are used to inspect the surface structure, ensuring the desired periodic pattern is formed.

PSS not only alters the surface morphology of materials but also improves their optical, electrical, and mechanical properties, making them potentially valuable in many fields. It is widely applied in the surface functionalization of various materials. In optoelectronics, PSS can be used to enhance light absorption or reduce reflection, thereby improving the efficiency of solar cells and photodetectors. In the biomedical field, the formation of specific nanostructured PSS can improve the cell compatibility and bioactivity of biomaterials.

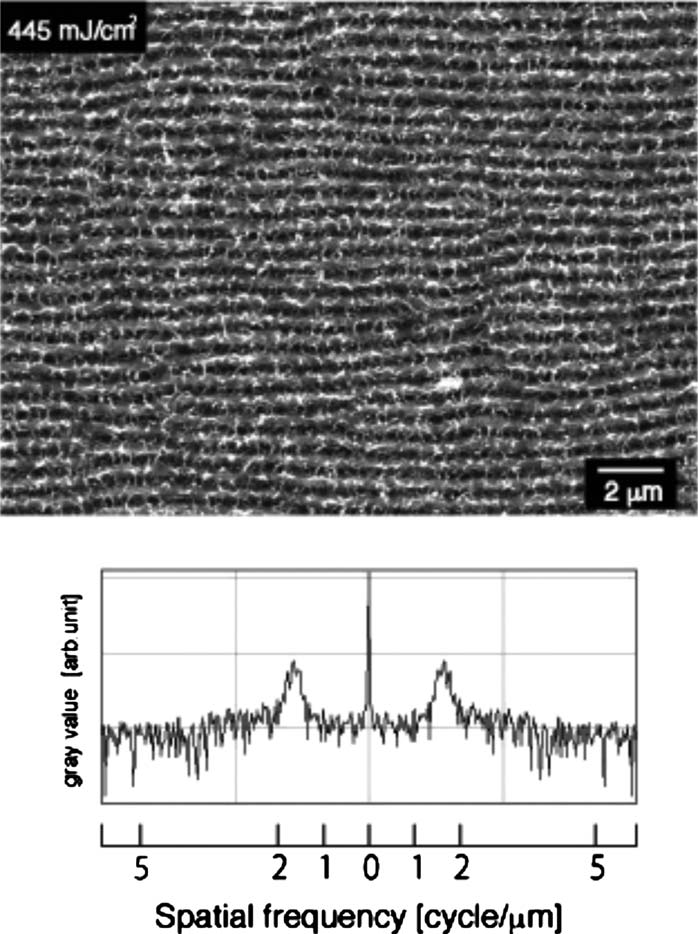

SEM image of the periodic structure on the tungsten surface generated by 50 pulses of 160 fs laser at 445 mJ/cm² and Fourier transform spectrum. [1]

Additionally, PSS is also applied in the development of sensors, surface design of catalysts, and improving the wettability and friction properties of materials. For example, by forming PSS on metal surfaces, surfaces with superhydrophobic or superhydrophilic properties can be created, which is of significant importance in materials science and surface engineering.

Femtosecond laser irradiation of lithium niobate (LiNbO₃) crystals to prepare periodic surface structures provides the possibility of generating nanogratings or nanostructures on wide-bandgap materials.

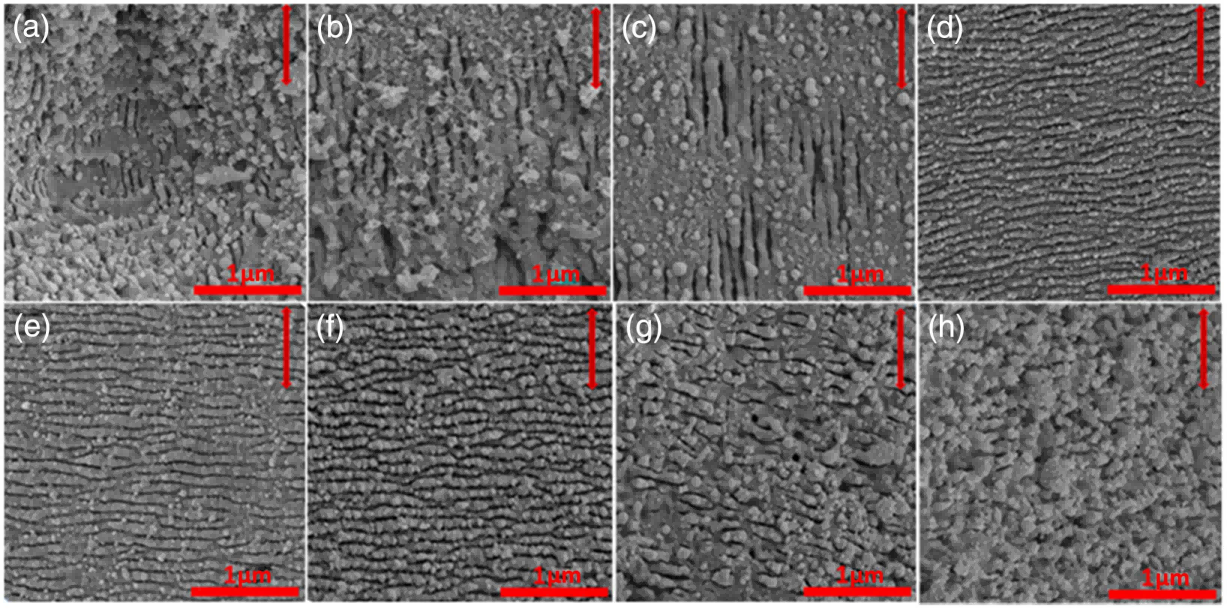

SEM images of the laser-treated LN surface in a nitrogen environment at sample temperatures of (a) 28°C, (b) 100°C, (c) 200°C, (d) 300°C, (e) 400°C, (f) 500°C, (g) 600°C, and (h) 800°C. Fluence: 7.0 kJ/m²; N₂ pressure: 500 Torr; scanning speed: 2 mm/s. The red double arrows indicate the polarization direction of the incident laser. [3]

Femtosecond lasers play a key role in the fabrication of periodic surface structures. Due to their ultra-short pulse durations, femtosecond lasers can perform high-precision processing on materials without causing excessive thermal damage. This fine control allows for the creation of highly ordered and uniform periodic structures on the surfaces of various materials.

Femtosecond lasers also allow for precise control of the characteristics of the periodic structures, such as period, depth, and shape, by adjusting the pulse parameters. This flexibility makes femtosecond lasers an ideal tool for the fabrication of customized PSS, offering broad possibilities for materials design and surface engineering.

References:

[1]K. Okamuro et al. "Laser fluence dependence of periodic grating structures formed on metal surfaces under femtosecond laser pulse irradiation." Physical Review B, 82 (2010): 165417. https://doi.org/10.1103/PHYSREVB.82.165417.[2]A. Y. Vorobyev, Chunlei Guo; Femtosecond laser-induced periodic surface structure formation on tungsten. J. Appl. Phys. 15 September 2008; 104 (6): 063523. https://doi.org/10.1063/1.2981072

[3]Qiang Li et al. "Femtosecond laser-induced periodic surface structures on lithium niobate crystal benefiting from sample heating." Photonics Research (2018). https://doi.org/10.1364/PRJ.6.000789.

AI Assistant

AI Assistant