Fiber cutting plays a crucial role in modern industrial processing, serving as the key technology for precisely cutting various fiber materials. This technology is widely applied in fields such as textiles, composite materials, and optical fibers. The core of fiber cutting lies in the use of high-precision cutting tools, which include lasers, ultrasonic knives, or specially designed mechanical blades. Among these, laser cutting is particularly suitable for handling high-strength and high-density fiber materials due to its high energy density and precise control capabilities. This high-precision cutting method not only improves production efficiency but also ensures the quality and consistency of the cut products.

In the textile industry, fiber cutting technology is used to precisely cut fabrics for making garments, tents, and other textiles. The application of this technology has made the production of clothing and textiles more efficient and precise, meeting the market demand for diversified and personalized products. In the aerospace and automotive industries, fiber cutting is used to manufacture components made from carbon fiber and other composite materials. These materials are known for their high strength and lightweight properties, making them essential in modern aerospace and automotive industries. Fiber cutting technology allows for the precise cutting of these complex materials, ensuring the accuracy and performance of the components.

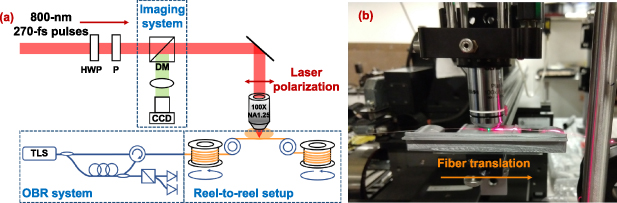

(b) Photo of the laser writing manufacturing device.

Additionally, fiber cutting is also crucial in the field of optical communication, particularly in the precise cutting and preparation of optical fibers. In optical communication systems, the quality of the optical fibers directly affects the transmission efficiency and stability of signals. Fiber cutting technology ensures the precision of optical fiber connections and the integrity of the fibers, thereby improving the overall performance of the optical communication system.

In these application fields, the use of femtosecond lasers is increasing, and they are playing an increasingly important role in fiber cutting technology. Femtosecond lasers are renowned for their high precision and rapid cutting capabilities, particularly when processing fiber materials that are high in strength, high in density, or sensitive to heat. One notable advantage of femtosecond laser cutting is its extremely short pulse duration, which significantly reduces the heat-affected zone of the material. This is crucial for achieving precise cuts while maintaining the integrity of fiber materials, especially during the cutting of optical fibers and high-performance composite materials, where such precision is essential.

In summary, fiber cutting technology is an indispensable part of modern industry, playing a vital role in multiple sectors. With the continuous advancement and application of femtosecond laser technology, the precision and efficiency of fiber cutting have been significantly improved, bringing new possibilities and higher production efficiency to these industries. The unique advantages of femtosecond lasers in enhancing the quality and efficiency of fiber material processing suggest that they will play an even more important role in the future of fiber cutting technology.

References:

(1)Mohan Wang et al. "Femtosecond laser fabrication of nanograting-based distributed fiber sensors for extreme environmental applications." International Journal of Extreme Manufacturing, 3 (2021). https://doi.org/10.1088/2631-7990/abe171.

AI Assistant

AI Assistant