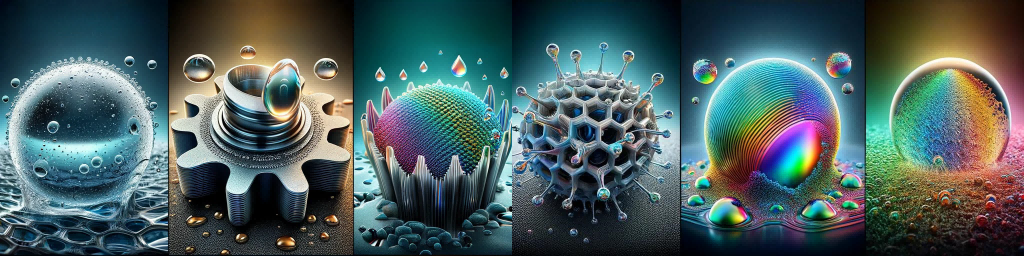

The research and application of surface micro-nano structures hold significant importance in various fields such as materials science, optical engineering, and biomedical science. By precisely controlling the micro-nano structures on surfaces, materials can be endowed with unique properties such as superhydrophobicity, improved frictional characteristics, and special optical properties, which have broad applications and significant implications across multiple domains. Below are some of the main characteristics and their applications:

Improved Frictional Characteristics: Micro-nano structures can be used to adjust the frictional properties of material surfaces. For instance, in industrial machinery components, precisely designed surface structures can reduce wear and friction, thereby extending the equipment's service life.

Enhanced Chemical and Biocompatibility: In the biomedical field, surface micro-nano structures can improve the compatibility of materials with biological tissues, promoting cell growth and adhesion. Examples include the surface design of medical devices for implantation or tissue engineering scaffolds.

Femtosecond laser machining technology plays a crucial role in realizing these applications. It not only provides a non-contact machining method, reducing the risk of material contamination, but also allows us to manipulate the microstructure of materials with unprecedented precision. As technology advances, we can anticipate innovative applications of surface micro-nano structures in more fields, thereby driving progress in materials science and related technological domains.

References:

(1)

(2)A. Vorobyev et al. "Femtosecond laser structuring of titanium implants." Applied Surface Science, 253 (2007): 7272-7280. https://doi.org/10.1016/J.APSUSC.2007.03.006.

(3)Cao Jing et al. "Engineering the crystalline silicon surface by femtosecond laser processing in liquid: Hierarchical micro/nanostructure and amorphization." Materials Chemistry and Physics, 248 (2020): 122909. https://doi.org/10.1016/j.matchemphys.2020.122909.

(4)Yan Wang et al. "Review of femtosecond laser induced surface periodic structure." , 11193 (2019): 111930V - 111930V-12. https://doi.org/10.1117/12.2537876.

(5)Jiale Yong et al. "Bioinspired underwater superoleophobic surface with ultralow oil-adhesion achieved by femtosecond laser microfabrication." Journal of Materials Chemistry, 2 (2014): 8790-8795. https://doi.org/10.1039/C4TA01277A.

(6)Peixun Fan et al. "Rapid fabrication of surface micro/nano structures with enhanced broadband absorption on Cu by picosecond laser.." Optics express, 21 10 (2013): 11628-37 . https://doi.org/10.1364/OE.21.011628.

AI Assistant

AI Assistant